Friction. Parameters. Friction States

Parameters. The useful power at the output shaft of the internal combustion engine (effective power Pe) is lower than the internal power at the piston (indicated power Pi). The difference is referred to as the friction loss Pr.

The friction loss includes the losses of the individual engine components such as the engine proper (crankshaft, connecting rods, pistons with piston rings), the valve train including the timing gear, and the requisite auxiliary drives. The internal power also allows for the losses due to the charge cycle, where the operating states and, consequently, the drive powers of the auxiliaries are often defined differently in the various standards. The friction loss reduces the engine power available at the output shaft and, thus, also influences the fuel consumption of the engine.

Analogous to the effective and indicated mean pressure, the mean friction pressure pmr is used to compare different engines with different swept volumes.

The friction of a complete engine includes the friction losses or drive powers of the individual components:

- Engine, consisting of

(a) Crankshaft main bearing with radial shaft seal rings

(b) Connecting rod bearings and piston group (pistons, piston rings, and piston pins)

(c) Any mass balancing systems

- Valve train and timing gear

- Auxiliaries, such as

(a) Oil pump, possibly with oil pump drive

(b) Coolant pump

(c) Alternator

(d) Fuel injection pump

(e) Radiator fan

(f) Vacuum pump

(g) Air conditioning compressor

(h) Power steering pump

(i) Air compressor

Friction States. Depending on the lubrication prevailing at the various friction points in the engine, different friction states occur. The most important are

- Solid friction (Coulomb's friction)

Friction between solids without fluid intermediate layer.

- Boundary friction

Friction between solids with an applied solid lubricant layer without a fluid intermediate layer.

- Mixed friction

Fluid friction and solid friction or boundary friction occur simultaneously; the lubricant layer does not completely separate the two friction layers from one another, and a certain contact occurs.

- Fluid friction (hydrodynamic friction)

A liquid (or gaseous) substance between the two friction layers completely separates the two from one another. In the internal combustion engine, the movement of the friction surfaces against one another creates the hydrodynamic supporting effect of the intermediate substance.

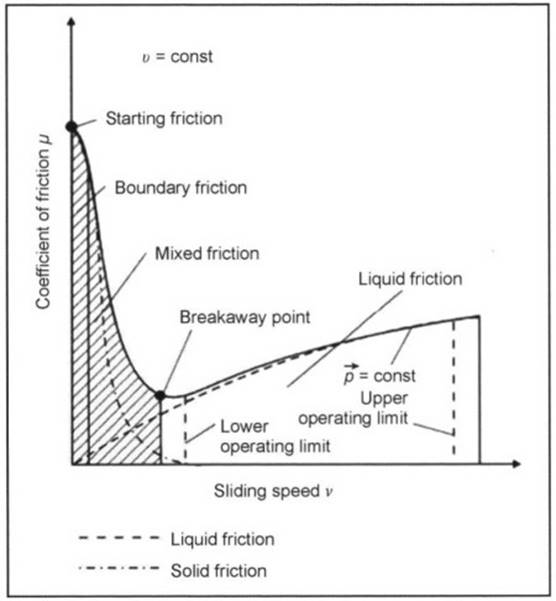

The occurrence of the different friction states is explained below using an example. In a hydrodynamic plain bearing, the different friction states occur as the engine passes through the engine rev band. The Stribeck curve in Fig. 9-1 shows the relationship between the coefficient of friction λ and the shaft speed n or the sliding velocity v at constant temperature (or constant viscosity ⴄ).

Fig. 9-1. Stribeck curve

The overall friction is made up of the two portions solid friction (or boundary friction) and fluid friction. At a standstill we have static friction. At low engine revs we first have solid friction and boundary friction, and then the mixed friction band occurs in which the friction decreases with increasing engine revs with a corresponding increasing buildup of a hydrodynamic supporting film.

The breakaway point in this model representation is the point at which the hydrodynamic supporting film can completely separate the surface roughnesses of the two friction partners. The engine speed at which this state is achieved is also referred to as the transitional speed at which the minimum friction occurs. At engine speeds above the transitional speed, fluid friction occurs, and the friction increases again because of the increasing shear rates.

Increasing loads on the friction pair or decreasing viscosity of the fluid shifts the transitional speed upwards and extends the range of mixed friction.

Operating states on the left-hand branch of the Stribeek curve are unstable, as a brief variation such as an increase in engine revs or reduction in the load leads to a significant rise in the coefficient of friction and, hence, to an automatic amplification of the fault. For this reason, the operating point of a friction pair in continuous operation must be sufficiently far from the breakaway point on the right-hand branch of the Stribeek curve.

Date added: 2024-11-14; views: 339;