Influence of the Operating State and the Boundary Conditions

The operating state of the engine and the boundary conditions under which the engine is operated have a significant influence on the friction behavior. The most important parameters are described below.

Run-In State of the Internal Combustion Engine. In the first hours of operation, an adaptation of the friction partners takes place at the individual sliding points and with it a smoothing of the surface unevenness. This process involves a certain amount of wear and increases the friction loss of the engine. Thus, the running-in process takes place at different speeds for the different friction pairs and is completed in modem car engines after approximately 20-30 operating hours, but in individual cases only after more than 100 operating hours, so that the engine reaches a constant friction level. This remains more or less constant until engine components reach their service life limits, leading to an increase in the friction once again.

Oil Viscosity. Through the change in the shear forces, the viscosity of the lubricant has a significant effect on the conditions at the lubrication point. With otherwise unchanged boundary conditions, operation of the internal combustion engine with lubricating oils of different viscosities results in a change in the friction state. A lower viscosity of the lubricating oil means a lower load-bearing ability of the lubrication gap and, thus, a reduction in the lubricant film thickness.

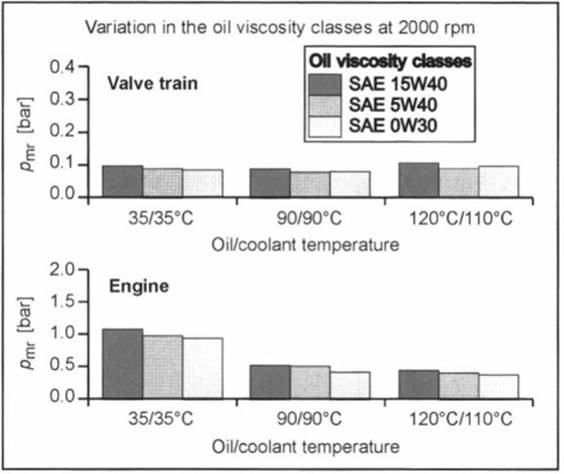

This is also associated with an increase in contact between solids in the mixed friction zone. Depending on the boundary conditions, the friction then drops if the hydrodynamic friction portion predominates or increases if the solid contact rises sharply. The behavior of different oils with different viscosities is illustrated in Fig. 9-3 for a car SI engine at 2000 rpm. With the boundary conditions prevailing here, a reduction in friction with decreasing oil viscosity was observed in the engine.

Fig. 9-3. Influence of the oil viscosity on friction

In the valve train, this reduction in friction is observed only at low temperatures. At higher temperatures, on the other hand, the friction increases because of the mixed friction conditions in the valve train caused by the lower oil viscosities. This change also has effects on the lubrication system and the oil pump drive power, as oil pressures and oil volumetric flows in the lubrication system are influenced by the various components and by the friction of the oil pump.

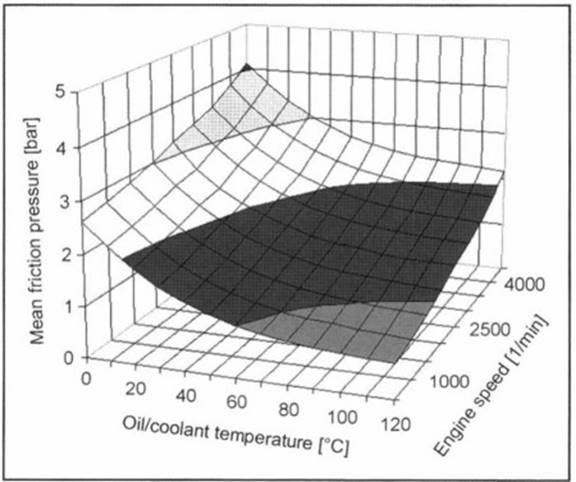

Temperature Influence. The operating temperature of the internal combustion engine, i.e., the temperatures of the components and the oil and coolant, influence the friction. The reasons for this are, first, the change in viscosity of the lubricant and, second, the change in the clearances in the various friction pairs. The effects of the changes in the fluid temperatures in the temperature range between 0 and 120°C are shown in Fig. 9-4. Even at fluid temperatures of approximately 20°C, the friction losses are already doubled compared with an engine at operating temperature (90°C). This is one of the reasons for the increase in fuel consumption after a cold start and for short journeys when the engine is not at operating temperature.

Fig. 9-4. Influence of the fluid temperatures on the friction

Engine Operating Point. The engine operating point influences the friction both via the parameter “engine speed” and via the load. The influence of the engine speed is attributable to the increase in the sliding speeds at the friction points of the individual engine components.

Increasing engine load has the following effects:

- Higher gas pressures and, thus, higher lateral piston forces, contact pressures of the piston rings, bearing loads, and forces for opening the exhaust valves

- Locally higher component temperatures and, hence, a possible increase in deformation

- Locally higher lubricant temperatures and, hence, a change in the friction state at the corresponding lubrication points

- Possibly modified drive power of the injection pump

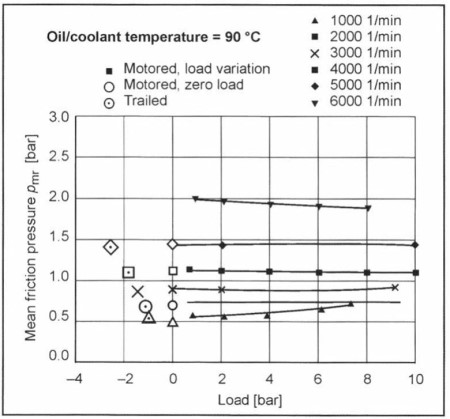

The effect of the influences of engine load and engine speed on the friction behavior of a car SI engine is shown in Fig. 9-5. The measurements collected on the motored engine with loads between 0 bar (zero load) and full load are also compared with the results from drag measurements (pme corresponds to the drag moment). The measurements in motoring mode at zero load show a good correlation with the measured values of the drag measurements at 0 bar.

Fig. 9-5. Relationship between friction and engine load/engine revs

The main influencing parameter is the engine speed: The engine friction increases at higher engine speeds. At moderate engine speeds, the engine load has only a very minor influence on the friction; i.e., the effects shown have only a minor influence or compensate one another in this engine speed range. At an engine speed of 1000 rpm, the friction increases with increasing load.

The friction of the piston increases at these low, sliding speeds because of the higher lateral piston forces. At high engine speeds, the friction decreases with increasing load. The reasons for this are the higher oil temperatures at the cylinder barrel at high engine powers, despite the same main oil temperature, and the partial compensation of the mass forces in the engine by gas forces.

Date added: 2024-11-14; views: 431;