Influence of Friction on the Fuel Consumption

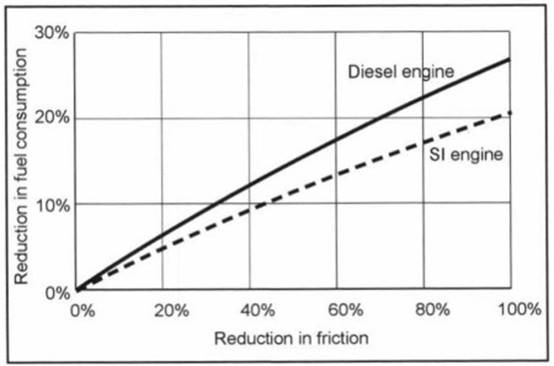

The mechanical efficiency ⴄm of an internal combustion engine is defined as the ratio of mean effective pressure pme to mean indicated pressure pmi.

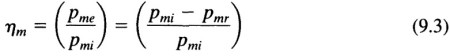

From this relationship, it is clear that at low engine loads, i.e., low mean effective and indicated pressure, the mechanical efficiency drops. The spreads of mean friction pressures of modem SI and diesel car engines are shown in Fig. 9-6. At an engine speed of 2000 rpm with values of 0.53-1.1 bar for SI engines and 1.02-1.4 bar for diesel engines including injection pump, the friction losses at full load are as high as 10% of the indicated power.

Fig. 9-6. Spread of the friction in motored engine mode (car engines)

In part-load operation, the mechanical efficiency drops so that the influence of friction on the fuel consumption continues to rise. A reduction in friction, therefore, offers a significant fuel savings potential and presents a worthwhile development objective. The span in each case between the engine with the highest and the engine with the lowest friction means not only an increase in fuel consumption, but also a reduction in the maximum power.

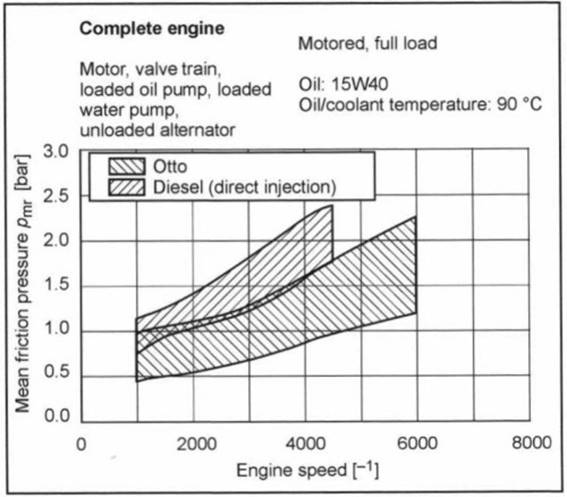

The development of friction over time is examined below, taking as an example the four-cylinder SI engine. Figure 9-7 shows the development of the mean friction pressure pmr on the basis of studies in drag mode at 2000 rpm. The first thing of note is that the spread of the values has a very large bandwidth, although a downward trend is noticeable that is marked clearly by the regression line.

Fig. 9-7. Development of the friction in four-cylinder SI engines (1.61–2.21 swept volume)

The friction behavior of the SI engine, in particular, has been significantly improved in recent years. In purely statistical terms, the friction of a 2 1 four-cylinder SI engine has been reduced by approximately 20% in roughly the last ten years. Extrapolation of the regression lines, however, results in an unrealistic reduction of the friction for the future.

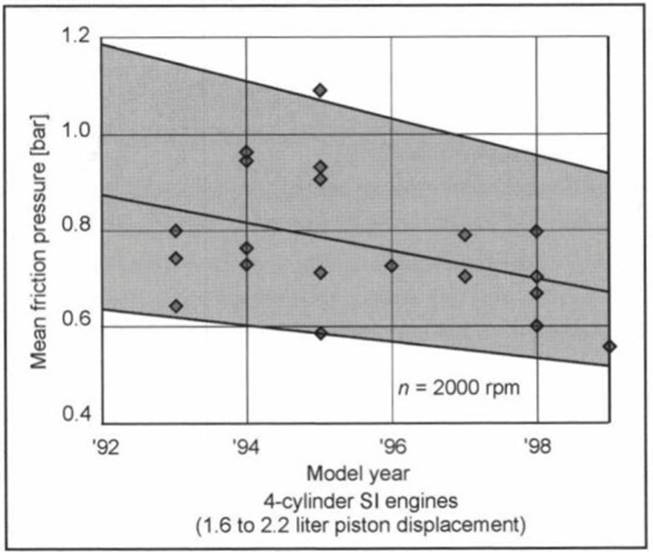

Fig. 9-8. Influence of the friction reduction on fuel consumption (friction considered at n = 2000 rpm)

The reduction of fuel consumption as a function of the mean friction pressure with the engine at operating temperature and an engine speed of 2000 rpm is shown in Fig. 9-8. The hypothetical case of the friction-free engine permits a reduction in fuel consumption of approximately 21% for the SI engine and of approximately 26% for the diesel engine. With the conventional measures used today (component optimization, roller valve train, modified pumps, heat management, etc.), it should be possible to exploit approximately 30% of this potential.

Date added: 2024-11-14; views: 440;