Environmental Concepts in the Chemical Industry

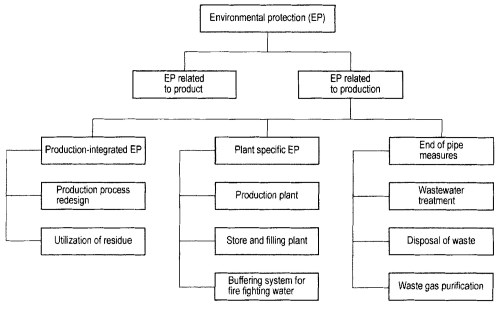

Review of the Environmental Concepts. Environmental protection in the chemical industry is divided into product related and production related areas. Environmental protection related to products covers the development and production of environmentally friendly products (e.g., paints, herbicides/pesticides, washing powder) and treatment of product wastes from processing and consumption (Chap. 4).

Environmental protection related to production covers the concept of the production-integrated environmental protection and additive environmental protection. Additiv environmental protection is the German term for end-ofpipe technology. This further subdivision can be examined in Figure 4.

Figure 4. Environmental protection

The third concept covers production plant including the subsidiary areas of storing and packing of raw materials and products. It is necessary to construct and operate these, so that material loss does not lead to environmental damage. Furthermore this includes retention systems for contaminated water draining out of burning plant during fires and containment systems for cooling water to prevent contamination of groundwater or surface waters.

The Concept of Integrated Environmental Protection. The idea of production-integrated environmental protection was implicitly described by A. W. von Hofmann (founder of the Royal College of Chemistry in London) as long ago as 1848: “In an ideal chemical factory ... there is, strictly speaking, no waste but only products (main and secondary by-products). The better a real factory makes use of its waste, the closer...it gets to its ideal, the bigger is the profit”.

In Germany, the concept of integrated environmental protection was introduced into the debate on environmental policy at the end of the 1970s [20]. It is being used to an increasing extent and is regarded as a mark of good environmental practice (e.g., in the report on the environment produced by the German Ministry of the Environment [21]). The term is defined differently in various social sectors. The following definitions are given as examples:

German Ministry for the Environment [22], [23]. Environmental protection must be integrated into all phases of the production cycle, i.e.,

1) Reduction or avoidance of harmful materials in the production process

2) Use of internal recycling and increase in energy efficiency in the production process

3) Development of alternative materials

4) Inclusion of the question of disposal in design of the product

5) Establishment of external recycling of production residues.

Industrial Management [24]. The following measures should be put into effect:

1) Avoidance of end-of-the-pipe techniques where possible — that means process design that avoids or reduces residues

2) Control over the environmental effects of pre-stages and subsequent stages of the process

3) Cooperation with suppliers, consumers, and waste disposal agencies

Matter and energy balances for the process itself and its pre-stages and subsequent steps are taken into consideration when setting up these measures.

Institut für ökologische Wirtschaftsforschung (Institute for Ecological Economic Research), Berlin [25]. Integrated environmental protection techniques either do not cause environmental pollution compared with traditional techniques or do so to a lesser extent. Recycling is regarded as an integrated environmental protection method only if it is an integral part of the production process, i.e., if a closed-cycle operation is used that reduces emissions. If recycling occurs separately from the production process, it is regarded as an additive technique.

Statistisches Bundesamt (German Federal Bureau of Statistics) [26]. The term “integrated environmental protection” is not used in statistics. Instead, distinction is made according to those parts of fixed assets that are concerned with environmental protection. The corresponding costs of a process change are also included in the statistics.

European Union [27]. The term “integrated techniques” includes

1) Clean production techniques

2) Processes based on materials that result in low environmental pollution

3) Reprocessing and recycling systems

Other Related Terms [28], [29]. The terms “clean production processes,” “clean production,” and “clean technology” are used predominantly in English-speaking countries. Clean production goes to the roots of environmental problems, and minimizes both emissions and costs. Clean technology is more than a “set of clean production techniques;” rather it is an approach to provide users with services and other benefits enabling the environment to be protected from excessive pollution.

The following terms should also be mentioned: “best available technology” and “nonhazardous production.” However, none of these terms have been clearly defined or distinguished from each other.

Verband der Chemischen Industrie (VCI, Association of the German Chemical Industry) [30]. In integrated environmental protection, the aim is to devise a process that causes as little pollution of air, water, and soil as possible, and in which integrated production methods enable residues to be utilized as far as possible. The technical and economic aims of the production process must nevertheless be fulfilled. This definition is also used by the Swiss chemical industry.

Date added: 2023-09-23; views: 605;