Surface Treatments. Materials for Piston Rings

The surface treatments listed below are employed with piston rings primarily to protect against corrosion during storage, to cover up minor surface defects, to improve break-in properties, secondarily to reduce wear at the running surfaces and flanks, and not at all to increase bum resistance during the run-in period.

Phosphating (zinc-phosphate and/or manganese- phosphate layers). The surface of the piston ring is transformed into phosphate crystals with chemical treatment. This phosphate layer is softer than the substrate material and thus wears away more easily, which accelerates ring wear-in.

Tin and copper plating. Both these metallic layers are applied by electroplating. Because of their softness they act somewhat like lubricants.

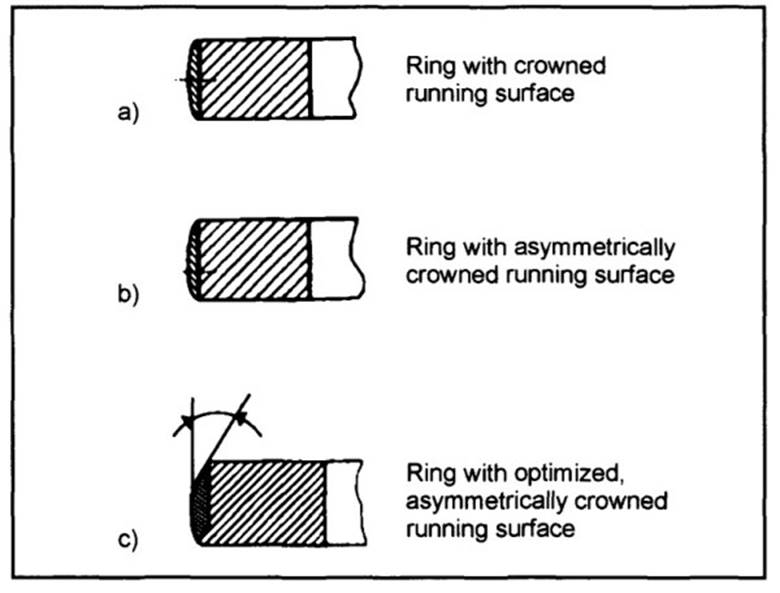

Contact Surface Shapes for Piston Rings. The contact surface shapes exert a major influence on the running properties of the piston rings. Symmetrically crowned, asymmetrically crowned, and optimized, asymmetrically crowned shapes such as those shown in Fig. 7-49 represent the state of the art. They have proven their suitability in practice, and this has been confirmed in many tribologic examinations.

Fig. 7-49. Contact surface shapes

In the optimized asymmetrical geometry (Fig. 7-49c), the upper third of the running surface is rendered conical, at an angle of less than 3°, so that the gas pressure in front of the ring counteracts in part the pressure behind the ring, thus avoiding excessive surface pressure at the running surfaces. Additionally, the amount of oil swept upward into the combustion chamber is minimized. Optimized crowning is used only in piston rings destined for use in diesel engines running at medium and high speeds.

Of great importance for the functional properties of the piston rings (oil consumption and blow-by) is the sharpness of the lower edge of the running surface.

Materials for Piston Rings. Determinants for the selection of the piston ring materials are demands for good running properties in both normal and emergency situations, for good elastic properties, and for good heat conductivity.

Great strength is required whenever extreme conditions such as high engine speeds or sharp rates of rise in the combustion pressure are present. The following materials may be used:

- Cast iron with flaked graphite, nonhardened. This is the “standard material for piston rings, with good break-in and emergency running properties and satisfactory wear properties. The hardness of this material ranges from 210 to 290 HB, and the values for resistance to flexure—350 N/mm2 at minimum—are relatively low. The standard material is used today only for the ring in the second piston ring groove and for oil control rings.

- Cast iron with flaked graphite, alloyed, hardened. The low shape retention properties of the standard material are improved by hardening. Resistance to flexures is at least 450 to 800 N/mm2, and hardness reaches 320 to 470 HB.

- Cast iron with spheroidal graphite (nodular cast iron), alloyed, and hardened. This type of cast iron is distinguished particularly by great resistance to flexure, of at least 1300 N/mm2, and hardness of from 310 to 470 HB. Because of its high resistance to flexure, nodular cast iron is given preference for rings mounted in the first piston ring groove.

- Steel. Because of its great breaking strength, steel is used, for example, at low ring heights (h ≤ 1.2 mm) for gasoline engines and in diesel engines with steep rates of pressure rise. Steel is also used for the rails and spacer springs in oil control rings as well as in profiled oil control rings.

Date added: 2024-04-24; views: 628;