Metal-Elastomer Seals. Special Metaloseal Gaskets

Metal-elastomer seals, Fig. 7-302, differ from the elastomer seals described in the previous section in that they have a metal insert at the center of the material (Fig. 7-303). They are used primarily in automotive applications and are found in the coolant, oil, fuel, and exhaust areas.

The metal insert (substrate plate) is normally sheet steel that is toothed, perforated, or glued to a smooth surface.

Fig. 7-302. Metal-elastomer seals

Fig. 7-303. Structure of the metal-elastomer seal

The metal insert provides a number of benefits:

- Great tensile strength

- Mechanical ruggedness

- Good dimensional stability

- Benefits in terms of process technology (coil manufacture)

- Cost reductions by lowering the fiber content

- Differing sealing materials on the substrate

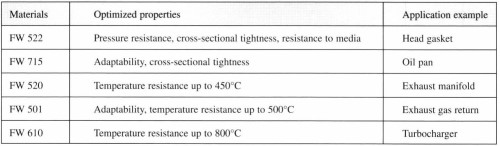

The substrate lends the required tensile strength, and thus other specific properties of the sealing materials can be carefully optimized, as is shown in Fig. 7-304 below.

Fig. 7-304. Survey of metal and metal-elastomer materials

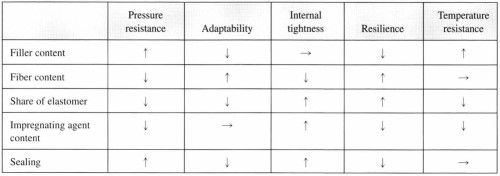

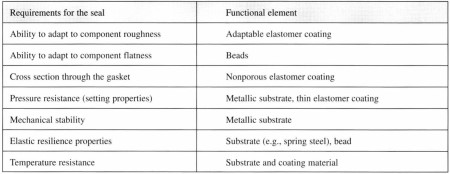

The specific properties of the materials listed in Fig. 7-304 are determined primarily by the composition of the sealing surface. Figure 7-305 indicates the most important adjustment parameters in the selection of the sealing layer.

Fig. 7-305. Materials parameters and their influence on functioning

The compound used for the sealing layers is determined most strongly by the thermal requirements. In a temperature range of up to 150°C, they are comparable with composite materials. In exhaust system seals, graphite and mica materials, with their great resistance to high temperatures, are used. As was described in the previous section on elastomer seals, the performance capacity of the metal-elastomer seals can be further boosted by an additional elastomer coating applied along a line. The seal quality over broader surface areas, in particular, can be improved significantly in this way.

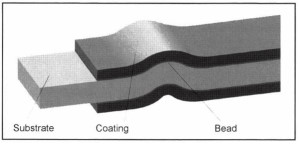

Special Metaloseal® Gaskets. The term Metaloseal® is derived from the words “metal sealing.” The fundamental structure for metal seals, Fig. 7-306, is based on a metal substrate that is coated with an elastomer, usually on both sides. One of the major advantages is found in the fact that any of a variety of metals can be combined with varying elastomer compounds to suit the application at hand.

Fig. 7-306. Ribbed oil filter head gasket

Thanks to the beads that are formed in addition, the substrate material’s properties can be matched perfectly to the sealing system, Fig. 7-307. As was already described in Section 7.21.2.1, the demands made on the sealing element can be satisfied only by metal gaskets that are coated and mechanically modified.

Fig. 7-307. Structure of metallic gaskets

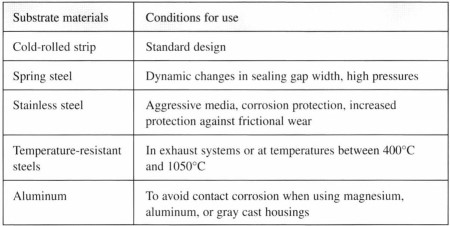

Substrate Materials. The choice of substrate materials has a direct influence on sealing properties. Ideal adaptability of the seal to the flange surfaces (macrosealing) can be achieved with two parameters: substrate material properties and bead geometry. The following table (Fig. 7-308) provides a survey of the various substrate materials available.

Fig. 7-308. Metaloseal® substrate materials

Standard material thicknesses lie between 0.20 and 0.30 mm. In special situations, thicker or multilayer gaskets can be used. This lets us achieve the best possible macrosealing properties for virtually every application, through the selection of suitable materials and bead geometries.

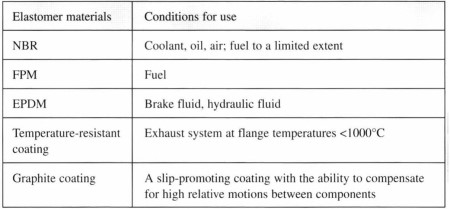

Coating. The selection of the elastomer is oriented primarily on the media to be sealed off and the prevailing operating temperature. One of the most important tasks in sealing is compensating for surface imperfections. Thus, the medium being sealed is kept from leaking across the surface area. The thickness at which each coating layer is applied can vary between 5 and 100 μm (on either side), depending on the particular situation. Listed in Fig. 7-309 are a few application examples for the various elastomer materials.

Fig. 7-309. Conditions for using the various elastomer materials

Functioning of a Metal Gasket. In the past it was necessary in some cases when using conventional elastomers to resort to engineering tricks in order to achieve a reliable seal. Thus, elastomer gaskets required exactly defined bolt torque in order to achieve sufficient surface pressures while at the same time avoiding excess pressure on the material, which would unavoidably damage the elastomer and result in leaks. In addition, there is always a conflict of goals among the various sealing properties when selecting the elastomer material (see Fig. 7-305, Section 7.21.2.3).

This is where the advantages of metallic seals become apparent. A bead pressed into the substrate reduces the surface pressure to a line-shaped pressure. Thus, at the same bolt forces, higher surface pressure values can be achieved or, conversely, the same surface pressures can be achieved at lower bolt force. With the use of a metallic substrate, all of the physical properties of a metal can be exploited. In addition, one creates a further magnitude that can be adjusted as required: the bead force.

Bead force is influenced both by a certain ratio of the bead’s height to width and by the shape of the bead itself—half or full bead—and can be modified individually to suit each application point. When the component is first tightened down, the elastomer coating is pressed into the surface by the force at the bead and closes any imperfections present there.

Fig. 7-310. Each of the various functional elements in the Metaloseal® gasket responds to a specific requirement

In addition, the degree to which the seal adapts to the flatness of the component is determined by the bead. The bead functions, in the classical sense, like a spring that develops the required sealing force in response to deformation. Described in Fig. 7-310 is the interrelationship between the component’s demands on the seal and the capabilities that the various functional elements have to exert an influence.

Date added: 2024-07-30; views: 529;