Special Cylinder Head Designs

In the VR series of engines made by VW five- and six- cylinder engines are made with a V-angle of 15° for a very compact configuration, in fact, a sort of synthesis of the inline and V-block engines. The one-piece cylinder heads are quite wide. Placing the intake and exhaust runners on either side of the cylinder head mandates differing intake and outlet port lengths for the two cylinder banks. Concepts with symmetrical gas exchange ports are also possible, but they require a minimum of three camshafts instead of the two used here.

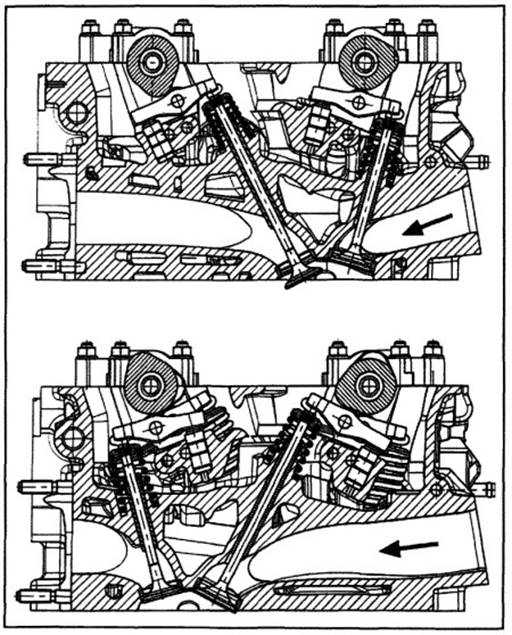

Figure 7-98 shows two sections through the mass-production, four-valve cylinder head, illustrating the various lengths of the gas ports. The cylinder head is provided with a camshaft shifter and uses precision-cast roller cam followers in the valve train. The design selected here, with its two camshafts, permits the spark plugs to be located at the center by adjusting the valve lengths.

Fig. 7-98. Sections of the type VR four-valve cylinder head made by Volkswagen

The difference in valve lengths is 33.9 mm. The valve diameters are 31 mm for the intake valves and 27 mm for the exhaust valves; the valve stem diameter is 6 mm. The combustion chambers of the two cylinder banks are almost mirror images of one another. The angle between the intake and exhaust valves is 42.5°.

The crossflow concept used in the VR cylinder head requires differing angles for the valves in relation to the cylinder centerline: 34.5° for the long ports and 8.0° for the short ports. In addition, the angles differ in relation to the port axes. To achieve uniform combustion in both cylinder banks, the short and long intake ports have to be tuned to achieve uniform flow-through and tumble effects.

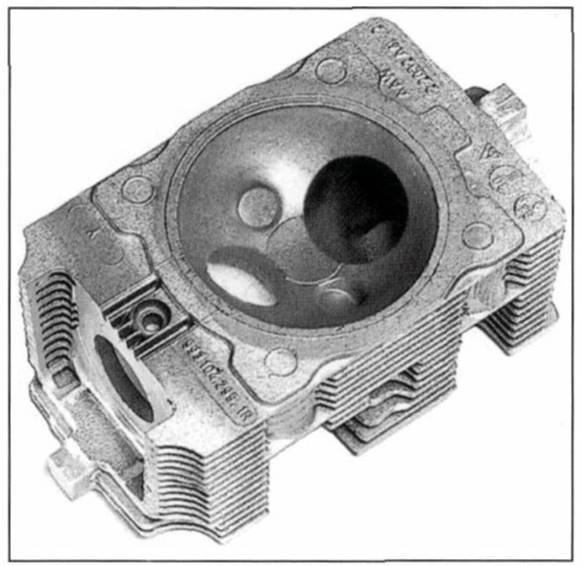

Air-cooled cylinder heads are very rare in passenger cars. The two-valve cylinder head for a six-cylinder boxer engine made by Porsche and shown in Fig. 7-99 has been supplanted in the current series by water-cooled, four- valve cylinder heads. To handle the degree of heat dissipation required at the cylinder head, cooling fins with large surface areas are needed in addition to the existing cooling fan.

Fig. 7-99. Air-cooled cylinder head made by Porsche

In this example, a ceramic port liner is cast in place in the cylinder head. Its insulating effect limits the amount of heat transferred into the cylinder head. In addition, this keeps the exhaust temperature high, accelerating catalytic converter warm-up following a cold start.

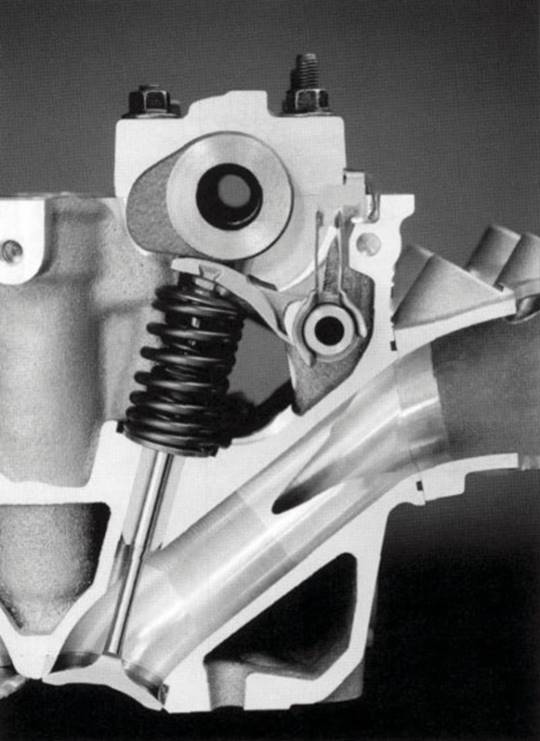

High engine speeds and with them very lightweight valve train components are required for sports engines with their extremely high volumetric efficiency. The masses in motion are kept as small as possible. Here it is advisable to eliminate heavy hydraulic valve play compensation elements. An example of such a design has been realized by BMW in a six-cylinder engine with precision-cast cam followers and mechanical valve play adjustment.

These sliding-type cam followers are very lightweight and rest on a shaft inserted into the cylinder head. In selecting the lever ratio for the cam follower, component stiffness was given precedence over minimizing the amount of installation space required.

The rocker arm drive uses a 1:1 lever ratio in order not to induce any bending loads, Figure 7-100. The four-valve cylinder head used here is a one-piece unit cast in a steel die. A cross-flow cooling concept is used here. Integrated into the cylinder head is an air distribution line into which supplementary air is blown. Splitting off from this line, which is 12 mm in diameter, are 4 mm bores leading directly into the exhaust port, next to each exhaust valve.

Fig. 7-100. Four-valve BMW cylinder head with sliding cam followers

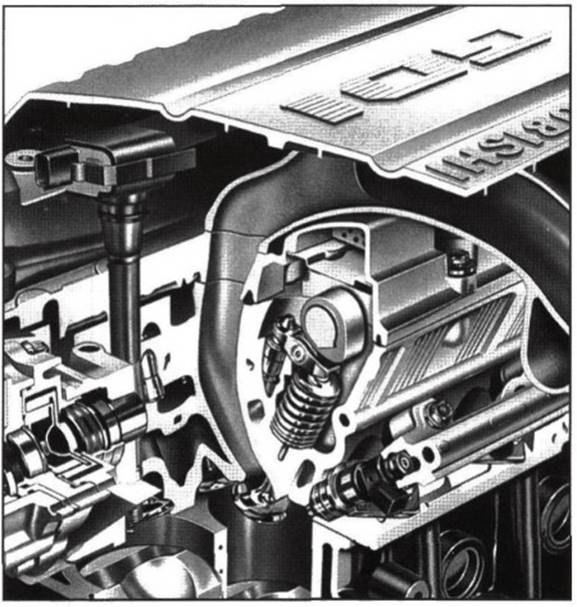

Direct-injection gasoline engines are currently being developed to readiness for mass production all over the world. It is necessary to free up space in the cylinder head, next to the spark plug, to accommodate the injection nozzle, a situation similar to that seen in direct-injection diesel engines. Space is tight even for a four-valve concept. Developing and fine-tuning the locations and shapes of the gas exchange ports is extremely difficult because of the charge stratification associated with the combustion process.

Fig. 7-101. Cylinder head for a direct-injection gasoline engine made by Mitsubishi

Figure 7-101 shows a section of a four-valve cylinder head used in mass production for a direct-injection engine built by Mitsubishi. The introduction of the air through the intake port is effected, from the intake manifold, at the top surface of the cylinder head to induce a defined tumble effect in the flow, matched to the shape of the bowl in the piston crown. The valves are actuated by roller cam followers. The injection nozzle is located toward the side, at the cylinder head. The spark plug is located at the center of the cylinder head.

Bibliography:

1. Hannibal, W., and K. Meyer, “Patentrecherche und Uberblick zu vari- ablen Ventilsteuerungen,” Lecture, Haus der Technik, 2000.

2. Flierl, R., R. Hofmann, C. Landed, T. Melcher, and H. Steyer, “Der neue BMW-Vierzylinder-Ottomotor mit VALVETRONIC,” in MTZ Motortechnische Zeitschrift, Vol. 62, 2001, No. 6.

3. Hannibal, W., and F. Lukas, “Rechnergestutzte Auslegung des Audi-Funfventil Zylinderkopfkonzeptes,” in MTZ Motortechnische Zeitschrift, Vol. 55, 1994, No. 12.

4. Dong, X., “Offnungsquerschnitt von Ventilen,” in MTZ Motortechnische Zeitschrift, Vol. 46, 1985, No. 6.

5. Schafer, F., S. Barte, and M. Bulla, “Geometrische Zusammenhange an Zylinderkopfen,” in MTZ Motortechnische Zeitschrift, Vol. 58, 1997, Nos. 7/8.

6. Eidenbock, T., R. Ratzberger, J. Stastny, and W. Stiitz, “Zylinderkopf in Vierventiltechnik fur den BMW DI-Dieselmotor,” in MTZ Motortechnische Zeitschrift, Vol. 59, 1998, No. 6.

7. Krappel, A., W, Riedl, D. Schmidt-Troje, and J. Schopp, “Der neue BMW Sechszylindermotor in neuer Hubraumstaffelung und innovativer Leichtbauweise,” in MTZ Motortechnische Zeitschrift, Vol. 56, 1995, No. 6.

8. N.N., “Becker CAD CAM CAST,” Becker GmbH, Steffenberg-Quotshausen, 2001.

Date added: 2024-04-24; views: 627;