Functional Description of the Flat Seal

Functional Description of the Flat Seal. Rat seals are highly effective, cost-favorable seals both for a number of liquid media and for gases. A broad range of pressure and temperature loads can be managed. The requirements on the flange surfaces at the components being sealed are low; surfaces machined with the milling head are sufficient.

To achieve positive sealing for static, flat seals, sufficient surface pressure is guaranteed at all operating states: Influencing parameters such as operating media, fluctuations in temperature and operating pressure, engineering elements (such as bolts and sealing surfaces), the location of the gasket within the assembly, and the seal’s long-term influence on the sealing assembly have to be taken into account during engineering.

Thus, the following requirements apply for the sealing element:

- Adaptation to component surfaces (microstructure—roughness/macrostructure—not plane)

- Pressure resistance (setting behavior) under the influence of heat and/or operating media

- Tightness across the entire surface of the seal

- Cross-sectional tightness in the seal material

- Mechanical stability (tensile strength)

- Elastic resilience properties

- Temperature resistance

Consequently, the ideal seal is an elastic rubberized metal with great strength and resistance to media and temperatures.

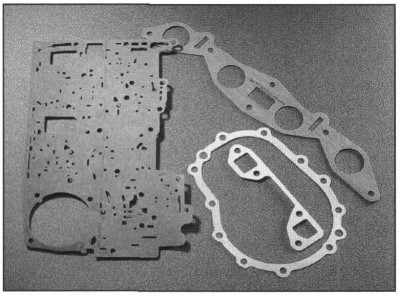

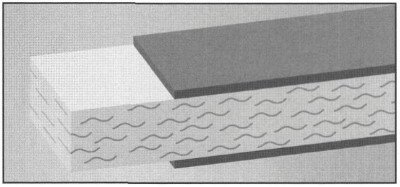

Elastomer Seals. Elastomer seals (Fig. 7-300) are employed in a broad spectrum of applications. They are made up of a composite material comprising fibers, fillers, and binders, Fig. 7-301. Since the end of the 1980s, rubber-asbestos elastomer seals have been replaced almost completely by asbestos-free qualities.

Fig. 7-300. Elastomer seals

Fig. 7-301. Elastomer seals—composite structure

In high-quality elastomer seals aramid fibers have largely been substituted for asbestos fibers. This material has superb mechanical and thermal properties. Cellulose and mineral fibers are used for economical gasket materials used in less critical areas.

The multitude of materials qualities available, such as EWP® sealing materials, makes it possible to select a suitable sealing material for almost every application. Elastomer sealing material is available in a range of thicknesses from 0.20 mm to over 2.5 mm.

The choice of material thickness makes it possible to “tune” a gasket for adaptation capacity, mechanical stability, and setting properties. The performance capacities of the elastomer seal can be further improved by applying additional elastomer layers along a line. In these areas the prescribed preload force on the surface (low sealing pressure) is reduced to narrow linelike areas (high sealing pressure).

Elastomer seals are cut on modem CNC water jet machines. Gaskets are cut without conventional tools when this technology is employed.

The limits for the use of asbestos-free elastomer seals are found in areas that are subjected to severe thermal loads.

Date added: 2024-07-30; views: 513;