Lubrication System. Oil pumps

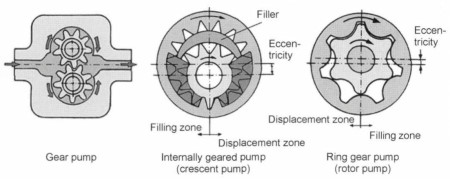

Oil pumps: Recirculating positive-displacement pumps—gear and ring gear pumps—of various designs are used for vehicle engines: External gear pumps, internal gear pumps (crescent pumps), and ring gear pumps (rotor pumps). These pumps are compact, have high efficiencies, exhibit a good intake behavior, and are suitable for a wide range of viscosities of the fluids to be pumped. The change in volume necessary for pressure boosting with positive-displacement pumps is affected by the meshing of the gear wheels. The displacement is calculated from the tooth geometry and the pump speed (Fig. 8-11).

Fig. 8-11. Types of engine oil pump (schematic)

Evaluation criteria for oil pumps are delivery characteristics, efficiency, sensitivity to cavitation, noise development, installation size, weight, and manufacturing costs. Important factors are a low intake head and a rapid pressure buildup in the oil circuit. The transport losses have to be covered, and the centrifugal force in the main bearing journals and the flow resistances of the oil consumers (bearings) have to be overcome. The pressure losses from the pump to the cylinder head lie in the order of approximately 1.5 to 2 bar. The flow velocity of the lubricating oil in the lines should not exceed 3 to 4 m/s.

Oil pumps are mounted on the crankshaft or engine block or in the sump. Mounting on the crankshaft permits an easier design and is cheaper (roughly 50% less expensive than installation in the sump), but it also forces larger impellers and higher pump speeds to be used than is really necessary. The power consumption is therefore significantly higher, irrespective of the pump type. Furthermore, the wobbling of the crankshaft has to be compensated, in ring gear pumps either by mounting the inner rotor in the pump housing or by centering the inner rotor on the crankshaft.

If the pump is located in the sump, the intake head is lower and the pump draws in oil better during starting. In addition, lower pump speeds can be used (e.g., gear ratio 1:1.5), therefore reducing the drive power. One disadvantage here is the complexity of the drive with chain, toothed belt, gear, or worm drive.

The delivery characteristic of recirculating positive-displacement pumps is dependent on the pump speed.

With increasing pump pressure, the volumetric efficiency drops because of the leakage losses. The oil demand of the engine, however, is more or less independent of the engine speed, so that with increasing engine revs the difference between delivery and demand becomes even larger. The individual oil consumers have different requirements: The bearings require a specific oil volumetric and hydraulic actuators a specific pressure.

For the camshaft adjustment mechanism, for example, higher deliveries are required; a dedicated secondary pump is provided for the cylinder shutoff. The design of the pump for a minimum oil volumetric flow at (hot) idle speed—i.e., low engine revs and low viscosity of the oil—means that with increasing engine revs, oil has to be bypassed above a certain counterpressure so that roughly 50% of the hydraulic energy is transformed into heat.

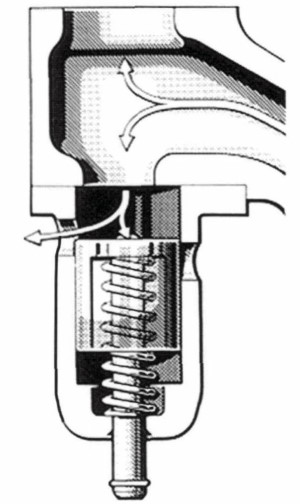

A distinction is made between control valves that are controlled directly by the system pressure and valves that are controlled indirectly, i.e., by both the system pressure and a given pilot pressure (Fig. 8-12).

Fig. 8-12. Directly driven control valve (Mercedes-Benz)

For additional consumers such as exhaust gas turbochargers, more oil has to be delivered. In addition, a reduction in the engine idle speed to lower the engine losses results in a significantly increased delivery at high engine revs. The disparity between the oil to be delivered at low engine revs and the oil volume actually required at high engine revs becomes even greater.

For this reason, efforts are made to adapt the pump characteristic better to the oil requirement of the engine by controlling the pump, by using register pumps, by varying the eccentricity on pumps with internal gearing, by using intake control for ring gear pumps, by axial shifting the secondary gear on pumps with external gearing, or by isolating the pump drive from the engine speed with the use of electric drives for the pump. However, such solutions demand a careful comparison of the design complexity and the additional weight and costs against the power savings that can be achieved.

For four- to six-cylinder engines, the oil demand is 40 to 100 1/min, and eight-cylinder engines require around 100 to 1201/min. As a rough estimate the crankshaft main bearings of car engines require 3 1/min per bearing, the connecting rod bearings 4 to 5 1/min per bearing, the piston cooling 1.5 to 3 1/min per nozzle, the cylinder head about 12 1/min.

However, 50% to 60% of the oil volumes are spilled off. Engines with aluminum crankcases require slightly more oil as the clearances increase with the temperature because of the greater thermal expansion. The delivery pressure is approximately 5 bar. The drive powers of oil pumps for four- to six-cylinder engines lie in the range from 0.5 to 2 kW, for larger engines up to 5 kW.

Date added: 2024-07-30; views: 619;