Lubrication. Tribological Principles. Friction

Engine technology is based on machine elements of different kinds that, linked by form and function, act on and influence one another, e.g., by

- Kinematics: Generation, transmission, and inhibition of movement

- Kinetics: Power transmission at boundary surfaces

- Transmission and transformation of mechanical energy

- Transport processes: Transportation of liquid and gaseous media

Tribology plays an important role in these processes. According to DIN 50323, “Tribology . .. [is] the science and technology of surfaces influencing one another in relative motion. It covers the total area of friction and wear, including lubrication, and includes appropriate boundary surface reciprocal effects both between solids and between solids and liquids or gases.”

Here lubrication permits, improves, and ensures the function, profitability, and service life of the components and functional groups of the engine and the complete powertrain.

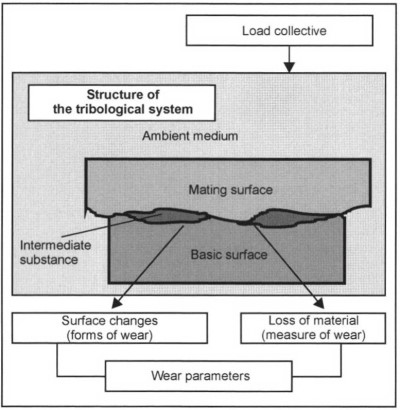

In the field of their interactions, tribological systems can be reduced to a basic structure (system elements) (DIN 50320): Basic surface, mating surface, intermediate substance (particles, fluids, gases), and ambient medium (Fig. 8-1).

Fig. 8-1. Schematic: Tribological system

Tribological stresses result from the movement process, effective forces (normal force), speeds, temperatures, and the duration of the load.

Friction. Friction is a complex phenomenon that is not easy to understand. It is ambiguous because it prevents movement as well as actually makes movement possible. There is no firm hold without friction—but also no movement away from the hold.

“Friction is an interaction between material areas of bodies in mutual contact. It opposes their relative movement. In the case of external friction, the areas of the substance in contact belong to different bodies, in the case of internal friction they belong to one and the same body.” (DIN 50 323, Part 3).

Friction depends both on the state of movement of the friction partners, adhesive friction (static friction, striction) and motional friction (dynamic friction), and on the type of relative movement of the friction partners.

- Sliding friction: Sliding, translation in the contact surface, relative movement of the sliding partners

- Rolling friction: Rolling, rotation about an instantaneous axis in the contact surface

- Combined sliding and rolling friction: Rolling with microscopic or macroscopic proportions of sliding

Friction is also dependent on the condition of the substance areas involved:

- Dry friction

- Fluid or viscous friction

- Gas friction

- Mixed friction

In the engine, friction is undesirable because part of the mechanical energy already “generated” with poor efficiency is converted again into thermodynamically “lower valency” heat. By reducing the viscosity and load-bearing strength of the lubricant, this heat impairs the function of components. In extreme cases, damage can occur because of the bearings running warm or hot.

Dry friction is a result of several mechanisms:

- Adhesion and shearing: Formation and destruction of adhesive connections in the contact surfaces.

- Plastic deformation: Deformation due to relative tangential movement.

- Scoring: Sliding partners of different hardness, the rough peaks of the hard partner press into the surface of the soft partner and/or a hard particle between the sliding partners is pressed into the surface of one or both.

- Deformation: Elastic hysteresis and damping.

- Energy dissipation: Frictional energy (mechanical energy) is transformed into heat and is lost.

Static friction exists when a body is pressed onto its counterpart under the effect of a resulting force and adheres at rest. Static friction is the basis for the transmission of power between all parts of the engine permanently joined by bolts, clamps, or compression fits, such as crankcase and cylinder head, crankshaft and drive flange, or mounting bore and bearing.

The critical coefficient of static friction μR for such connections depends on the material pairing, the surface condition, and the tribological conditions (lubrication); it is, therefore, a system property and not a material property.

In the case of sliding friction (friction of movement), fluid friction, in particular, is of the greatest relevance to engine technology; it presupposes lubrication. The relevant friction conditions for machine parts are represented in the Stribeck curve named after Richard Stribeck (1861-1950) as

- Dry friction with direct metallic contact between the sliding partners.

- Boundary friction when the sliding partners are covered with traces of the lubricant.

- Mixed friction as a combination of dry and fluid friction when the lubricant film between the sliding partners is partially interrupted.

- Elastohydrodynamic lubrication: If high pressures exist between the sliding partners, the pressure in the oil film increases the viscosity of the oil. This is why—despite essentially unfavorable conditions—a sufficient minimum lubricant film thickness is obtained (for example, contraform contacts: gear pairs, cam/cam follower, etc.).

- Hydrodynamic lubrication: Fluid friction with complete separation of the sliding partners from one another by a lubricant film.

Losses because of friction are included in the mechanical efficiency. As the quotient of the effective power Pe and the indicated power Pi, the mechanical efficiency includes all the mechanical losses from the piston to the crankshaft flange.

Furthermore, it also takes into account hydraulic losses (splash losses) and the drive powers of the ancillary machines necessary for operation of the engine. The mechanical efficiency of engines lies in the range from 75% to 90% at rated output and drops sharply at part load.

Date added: 2024-07-30; views: 462;