Lubrication System. Oil monitoring and burden

Oil monitoring: Because it is so vital for the engine, the oil supply has to be monitored.10 As a rule, the pump counterpressure is used as the monitoring parameter. This is problematical in that it is not the physically relevant parameter, the oil volumetric flow, but a dependent parameter, the pump counterpressure, that serves as the monitoring parameter.

On the one hand, this increases as a square of the flow velocity (in line with the volumetric flow), and, on the other hand, it is also dependent on the flow resistance. With increasing temperature, the viscosity (viscousness) of the lubricant decreases so that more oil has to be delivered to maintain the specified control pressure. If the line becomes clogged, the flow resistance increases so that, despite a lower oil volumetric flow, the pressure does not decrease. If, on the other hand, the coefficient of resistance drops because of an increase in bearing clearances, although more oil flows through the bearings, the pressure drops and incorrectly signals “low oil.”

For this reason, the oil pressure should be monitored at the end of the line, e.g., behind the last crankshaft bearing or in the cylinder head. Because the engine operator cannot keep an eye on the oil pressure gauge the whole time, he often notices a drop in the oil pressure only when it is too late, namely, from the generally disastrous consequences. For this reason, the drop in oil pressure should also be signaled acoustically.

Further monitoring parameters are oil temperature and oil level. Sensors are used for this purpose; it must also be possible to check the oil level manually using an oil dipstick with marks for the maximum and minimum oil levels.

Oil burden: The burden on the engine oil has increased continuously over the course of time: Because of smaller oil filling volumes, because of increasing powers as a result of higher engine revs and turbocharging, because of more compact engines (downsizing, particularly with the V-type engine) through more complex designs, longer inspection and oil change intervals, and because of widely (and frequently) changing engine loads and speeds. Furthermore, aerodynamically optimized body forms allow the temperature in the engine compartment to increase.

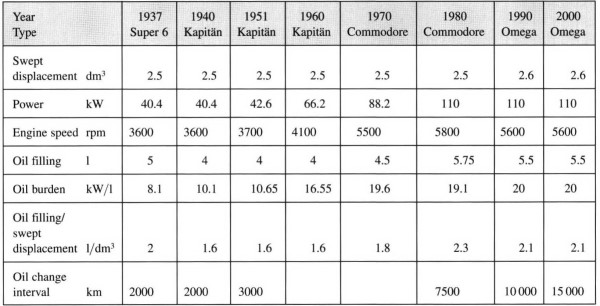

Fig. 8-13. Technical data of 2.5 1 Opel engine

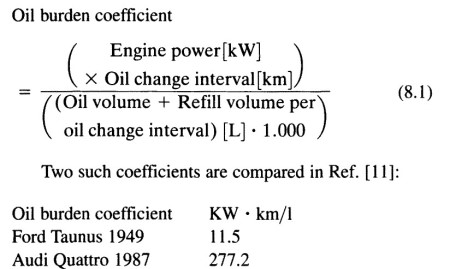

The oil burden can be expressed in figures with various coefficients (Fig. 8-13), e.g., oil filling volume/swept displacement or oil filling volume/power. More precise information is given by the oil burden coefficient:

Oil consumption: The oil volume in the oil tank (sump) decreases during the course of the operating life because of oil losses and oil consumption. Oil losses occur when oil escapes between the rigid and moving parts of the engine. These can be the connection from the crankcase to the sump and cylinder head, the connection from the cylinder head to the cylinder head cover, the connections between oil filter and oil cooler, as well as leaking oil drain plugs and crankshaft seals.

The actual oil consumption results from internal leaks because of burning and/or evaporation of oil. Such leaks are caused by worn piston rings or piston ring grooves, mirroring in the upper area of the cylinder tracks, excessive clearance between valve stem, and valve guide or leaks in the turbocharger. The oil consumption can be estimated only roughly because it depends on a large number of parameters that change during the course of the engine life. “Normal” consumptions for car engines are 0.1 to 0.25 (0.5) 1 per 624 mi. A constant oil level does not always mean that no oil is being consumed because the oil consumption can—particularly in diesel engines—be “compensated” by the ingress of fuel into the oil system.

Oil change: The oil as a medium of lubrication is subject to a huge number of changes during the engine operation. These necessitate the periodic replacement of the oil fill (oil change). The oil change intervals have been significantly increased during the last decade. Criteria for the oil change are the content of liquid and solid foreign matter, the exhaustion of the additive effectiveness, and any impermissible changes in the viscosity. The filters have to be changed at the same time the oil is changed.

The oil change intervals are specified by the engine manufacturers depending on the engine type (gasoline, diesel), engine model, service life in km or mi, operating time in months, and the respective operating conditions; they vary widely for car engines from (3000 mi), 9.300 to 2.400 mi (18.600 mi). These intervals must be strictly observed. The old oil must be disposed of in the prescribed manner.

More recently, the development is towards flexible, load-dependent oil change intervals from 2.400 to 25.000 mi, corresponding to 1 to 2 years of operation. The crucial factor for the oil change interval is the condition of the oil. It deteriorates during the engine operation because of oxidation, the formation of organic nitrates, reduction in the additive effectiveness, and, in diesel engines, additionally the incorporation of soot.

Determining factors here are the engine size, i.e., the load on the engine, the operating conditions (cold start, hot running), and the oil grade. A sensor is used to monitor the operating temperature of the engine, the oil filling level, and the oil quality, where the dielectric constant is regarded as a criterion for the condition of the engine oil.

Date added: 2024-07-30; views: 568;