Camshaft Timing Devices

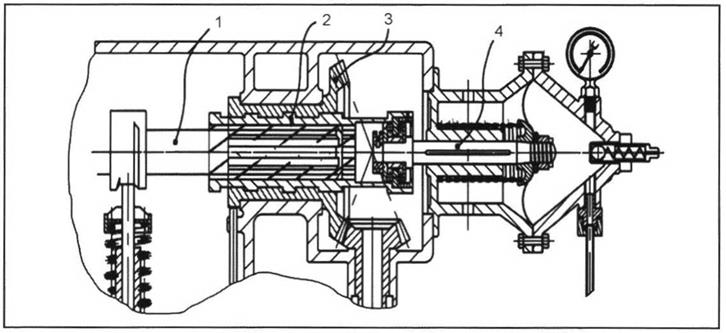

Overview of the Functional Principles of Camshaft Timing Devices. As early as September 29, 1918, a patent was issued for the adjustment of a spark-ignition engine camshaft. The desired variation during engine operation was attained with a sleeve with interior and exterior teeth and straight and helical teeth that moved axially between the camshaft and the drive wheel (Fig. 10-63). The angular position of the cam and camshaft were adjusted relative to the crankshaft.

Fig. 10-63. Patent of a camshaft adjuster from 1918

The inventor of this patent, Samuel Haltenberger, intended the timing device for an airplane engine to adapt output to different flight heights. The helical-toothed sleeve (2) is moved in an axial direction by air pressure using a timing device linkage (4). The relative angular position of the camshaft (1) changes in relation to the driving bevel gear (3) that is linked to the crankshaft. Based on the same functional principle of a straight and helical-toothed sleeve, in 1983 Alfa Romeo started mass producing a camshaft timing device for a two-valve engine with dual camshafts (Fig. 10-64).

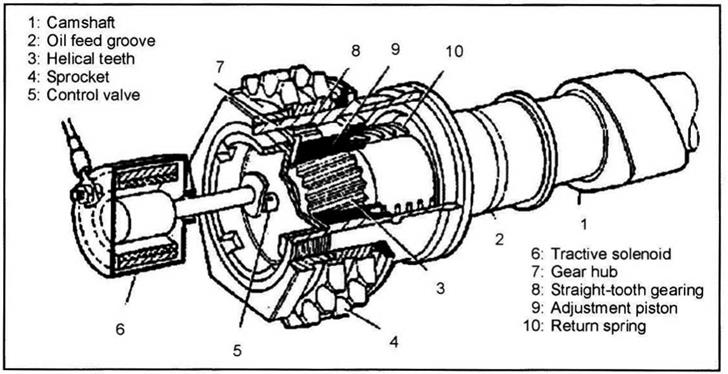

Fig. 10-64. Camshaft timing device by Alfa Romeo from 1983

The timing device is seated on the intake camshaft and enables the control times to be adjusted between two positions. While idling, the late control time position is held by a return spring (10), and an early control time is set depending on the oil pressure and speed. A solenoid (6) that actuates the control valve (5) applies the engine oil pressure to the helicaltoothed piston (9). The adjusting element is the helicaltoothed piston (9) that is moved by the oil pressure against the spring force. The helical teeth (3) on the piston and camshaft are used to rotate the camshaft relative to the driving sprocket (4) and, hence, to the crankshaft when the piston shifts axially.

The systems shown in Figs. 10-63 and 10-64 are all designs where a mechanical functional principle is used. This means that the force to actuate the valves flows only via components that are engaged by friction or are positively engaged. The adjusting elements such as the piston in the Alfa Romeo timing device in Fig. 10-64 can, however, be moved and held by oil pressure. For a camshaft timing device that operates based on hydraulics, a hydraulic component lies in the flow of force to actuate the valve. This is done using a quantity of oil that must be at a correspondingly high pressure to keep the positions of the adjusting elements stable.

The position of the camshaft timing device should logically be directly adjacent to the camshaft drive. The flow of force to drive the camshaft can be most easily interrupted here, and the camshaft adjustment can easily be varied by selecting the suitable adjusting element.

In researching the literature and known patent applications, one can find numerous different functional principles for camshaft timing devices. In a patent search, we found approximately 800 different applications. When the application dates are plotted over the last 20 years, we can see a strong rise over time in activities in this field. After the Alfa Romeo timing devices started being mass produced, the number of patent applications began to rise drastically. In Fig. 10-65, which illustrates the situation up to January 2000, the number of applications is counted from 1979 to 1999 from a compiled database. For 1998 and 1999, not all applications could be entered since there are 18 months between the application date and date of publication.

Fig. 10-65. Number of found patent applications and unexamined applications of camshaft timing devices from 1979 to 1999

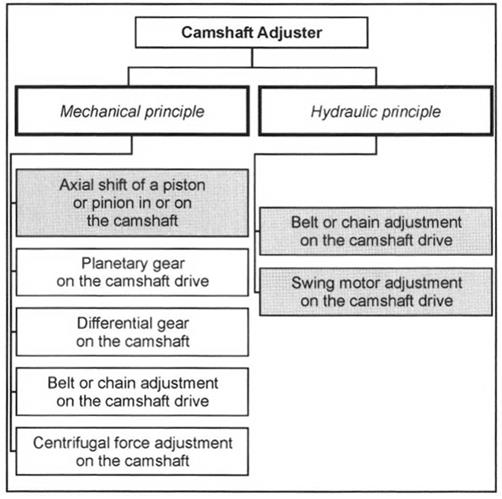

The known timing devices can be categorized according to their different functional principles. Figure 10-66 shows these principles. Essentially, the timing devices are systems that are based on either a mechanical or a hydraulic functional principle. The most frequent solution is to axially shift a piston to change the angle by using helical teeth. Basically, only three principles are used for production engines (with gray backgrounds in Fig. 10-66).

Fig. 10-66. Categorization of camshaft timing devices according to their functional principles

Belonging to the first group are systems that use helical toothing like Alfa Romeo’s approach based on a mechanical functional principle. A second solution is the hydraulically actuated chain timing device where the camshaft is rotated to the desired extent by adjusting the chain sag. Belonging to a more current group are systems with hydraulically actuated swing motors on the camshaft drive. Individual descriptions of the systems can be found in Section 10.4.1.3.

All camshaft timing devices for production engines are on the camshaft drive. The timing devices do not affect the valve stroke or valve opening time. Numerous other known systems exist. The sites at which the valve stroke and valve opening time are adjusted are usually between the cam and valve. This allows the camshaft timing devices to be combined with these systems.

An example of a system to change the valve stroke or opening time is the so-called “VTEC” system by Honda. This system allows different valve strokes and opening times by changing the transmission geometry between the cam and valve. These systems are used for many different engines (see also Section 10.4.2).

Date added: 2024-11-14; views: 399;