Valve Gear Designs

To control the charge cycles of four-stroke engines, mushroom valves are used almost exclusively, and they are sometimes used for two-stroke engines. The required actuating mechanism, including the valves themselves, is termed the “valve gear.”

A common feature of all valve gear arrangements is that they are driven via a camshaft that runs at halfcrankshaft speed in four-stroke engines. The different valve gears can be distinguished by

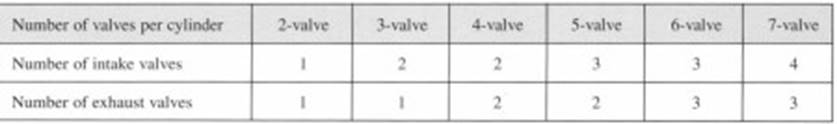

- The number of valves per cylinder (Fig. 10-2)

- The position of the camshaft

Fig. 10-2. Valve arrangements

Doubling the number of intake and exhaust valves to two is a sufficiently tried-and-true method to improve the volumetric efficiency and reduce the charge cycle work by providing larger flow cross sections. The advantages over a more complex valve gear are increased specific output, lower specific fuel consumption, and enhanced combustion. When this technical approach is pursued, we must ask if the conventional four valves per cylinder represent an absolute or relative optimum. In this regard, Aoi [SAE 860032] investigated four- to seven-valve arrangements.

The following terms are defined in this context:

- Valve area: circular area of the valve openings per cylinder

- Valve opening area: lateral surface when the valves are open

Assuming the same cylinder diameter, the five-valve arrangement has the largest valve opening area, which at this juncture refers to the intake valves that have the predominant influence on the sought effect (Fig. 10-3). Given the same pressure ratio, this arrangement has the highest flow rate and best volumetric efficiency. Given equivalent valve opening areas, the cylinder diameter could be somewhat smaller for five valves than for four valves. The more compact combustion chamber of the five valves, therefore, has advantages for output.

Fig. 10-3. Influence of the number of valves on the intake valve area and intake valve opening area

Nevertheless, four-valve spark-ignition engines have become widely accepted in passenger cars. This is primarily because the improvement attained with five over four valves is not worth the effort for most applications. This starts with the valve guide in the cylinder head and continues with the mechanical valve gear components. The lack of space in the cylinder head from new developments such as dual ignition or direct fuel injection also represents a problem that is difficult to solve. Figure 10-4 shows a four-valve engine with a radial valve arrangement, and a five-valve engine with a roofed combustion chamber.

Fig. 10-4. The 4- and 5-valve engine

Camshaft Position

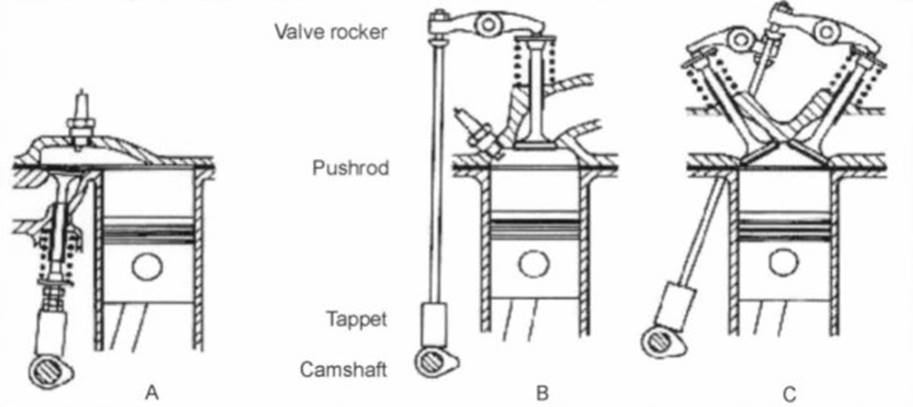

- Bottom camshaft

The camshaft lies below the dividing line between the head and block (Fig. 10-5). Standing valves (Fig. 10-5, A) that can be actuated directly by tappets produce an inferior combustion chamber, however (knocking, hydrocarbon emissions); this design is antiquated. Overhead valves (Fig. 10-5, В and C) require a tappet, pushrod, and valve rocker to be actuated. The valves can be arranged in parallel (Fig. 10-5, B) or in a V (Fig. 10-5, C).

Fig. 10-5. Valve gears with a bottom camshaft—A: standing valves; B and C: overhead valves

- Top camshaft

Camshafts above the head/block dividing line are usually used in modem, fast-running spark-ignition and diesel engines. The valves can be actuated via a valve lever or rocker arm, valve rocker, or tappet (Fig. 10-6). The advantage is that dispensing with the pushrod and tappet or valve lever or rocker arm reduces the unevenly moved mass and the elasticity of the valve gear.

Fig. 10-6. Valve gears with an upper camshaft

In today’s conventional valve gears, the transmission elements (valve rocker, valve lever, tappet, etc.) are pressed under spring force (valve spring) against each other or against the cam when the valve is open. This grip can be lost at high speeds. This does not hold true for desmodromic valves where lifting from the control cam is avoided by means of a second cam (Fig. 10-7); this makes valve springs unnecessary.

Fig. 10-7. Desmodromic valve

Valve clearance is also required. Because of the effort involved (manufacturing, servicing), this solution did not become popular.

Date added: 2024-11-14; views: 414;