Reduction of Mass. Factors Influencing Camshaft Loading

Similar to the situation for the vehicle as a whole or for the overall valve train, the camshaft as an individual component is subject to the necessity to reduce masses. On the one hand, the engine's static mass is minimized, while, on the other hand, the moving (rotating) masses have great influence on the dynamics of the total system.

At the same time, it is always necessary to reach a compromise among technical feasibility (minimum wall thickness, etc.), costs (materials, machining steps, etc.), and functioning (cam width, diameter of the base circle, torsional stiffness etc.).

The simplest possible option is hollow drilling or cylindrical hollow casting for camshafts (20% reduction in mass). When using hollow casting techniques with a graduated inner contour (profiled cavity), the mass is reduced even further. Figure 7-218 shows some examples of mass reductions in comparison with camshafts made of solid material and examples of chilled cast iron and steel cast camshafts with hollow profiles.

The assembled camshaft today presents the greatest potential for reducing masses. The steel tube’s wall thickness can be reduced further than the wall thickness in the casting process. Integrating the camshaft bearing into the camshaft itself (tube diameter = inner race diameter) permits additional savings in masses. An important design criterion for such shafts is the joint between the cams and the tube, with its influence on the moment, which can be transferred.

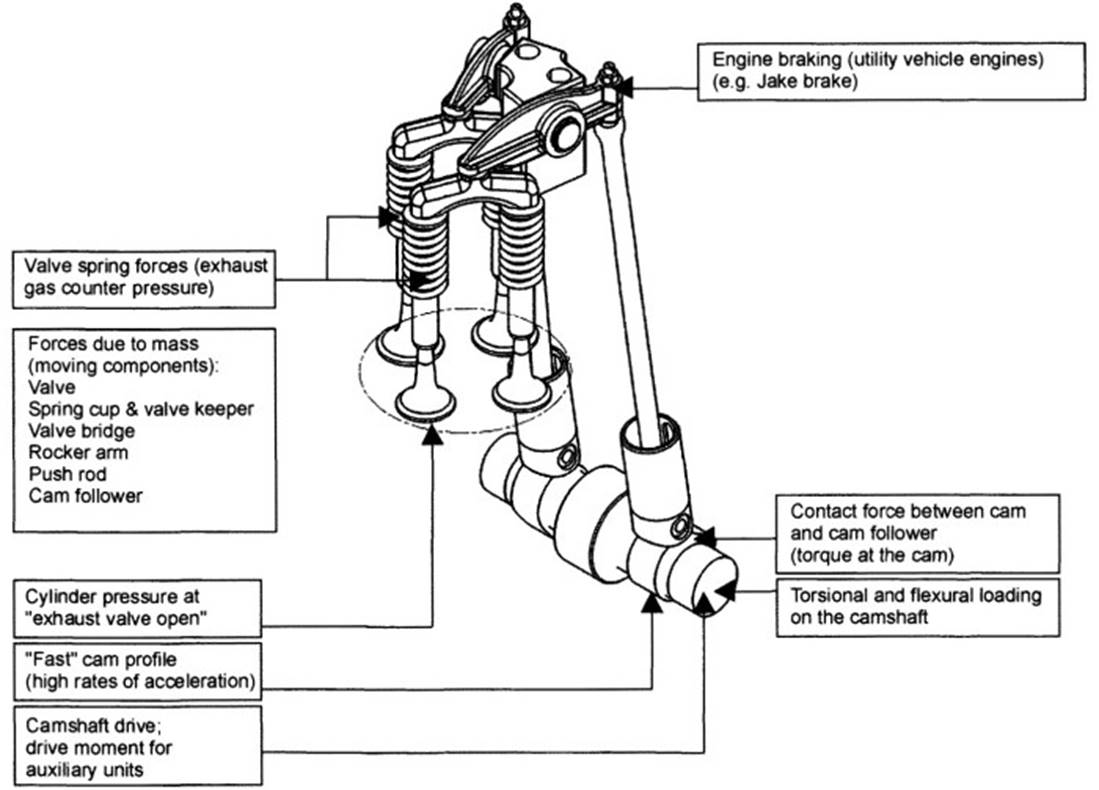

Factors Influencing Camshaft Loading. The kinematics of the valve drive is the primary determinant for camshaft loading. The peripheral geometric conditions such as the step-down ratio or cam profile (e.g., high acceleration rates) are decisive here, in particular. Moreover, the camshaft is loaded by the valve train masses in motion and the total forces exerted by the valve springs and exhaust gas counterpressure.

Fig. 7-219. Factors influencing camshaft loading

An integrated engine braking system can impose further and usually very significant loading on the camshaft (five to ten times the forces encountered during normal changes of gas charges). Figure 7-219 shows some of the influencing factors for camshaft loading.

The contact forces created between the cam and the camshaft induce both torsional and flexural moments in the camshaft which, together with the drive moment for auxiliary units, give the total torsional and flexural loads for the camshaft. In addition to the loading, the Young’s modulus for the cam and the cam follower and the crowning of the components in the contact area are decisive for pressures and deformations.

Date added: 2024-05-12; views: 688;