Valve Train Configurations

When using overhead valves (OHV) the camshaft is located in the engine block, with the lift motion transferred to the valve by tappets or cam followers, push rods, and rocker arms. The configuration used for this type of drive train is usually simpler, but the stiffness is markedly lower than in systems with an overhead camshaft (OHC) or double overhead camshafts (DOHC).

In the latter designs, the camshaft or camshafts are located in the cylinder head and driven off the crankshaft by gears, chains, or belts (and in a few cases toothed chains). The valves are actuated by rocker arms, cam followers, or valve lifters. The various types of valve trains used in passenger cars and utility vehicles and their application ranges are shown in Fig. 7-210. The materials listed here for the cams and cam followers are discussed later.

Fig. 7-210. Valve train configurations for passenger car, motorcycle, and utility vehicle engines

When the lift stroke is transferred to the cam follower (rocker arm, tappet, or valve lifter), one may differentiate between sliding contact and rolling contact. Current development trends are toward rolling contact in order to reduce drive losses and increase the tolerable loading. Another trend of simple valve lifter drives is toward sliding contact (without hydraulic clearance compensation) to reduce costs.

In addition to reduced friction losses (which means greater engine efficiency), the improved tribologic characteristics can also reduce wear. Where rolling contact is used, the tolerable surface pressure between the cam and the cam follower is considerably greater than for sliding contact. In the same comparison, Hertzian pressure rises because of the transition from sliding to rolling contact and the curved radii.

Materials with adequate rolling fatigue strength have to be selected when engineering for rolling contact; hardened steel (such as antifriction bearing steel) is normally used.

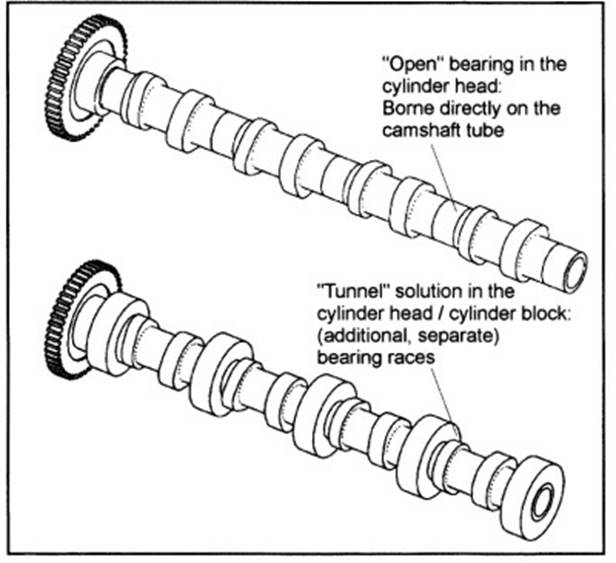

Fig. 7-211. Camshaft bearing variants

Two variants in the camshaft bearing concept are “open bearings” and “tunnel bearings.” In the open bearing concept the bearing races are part of the camshaft; split bearings have to be used to support the camshaft. In tunnel bearings the camshaft has bearing races with a diameter greater than the maximum cam height. The camshaft can thus be slid completely into solid bearing races in the cylinder head or the engine block, Fig. 7-211.

Date added: 2024-05-12; views: 972;