Plastics. Classification of Plastic Products for Building Construction

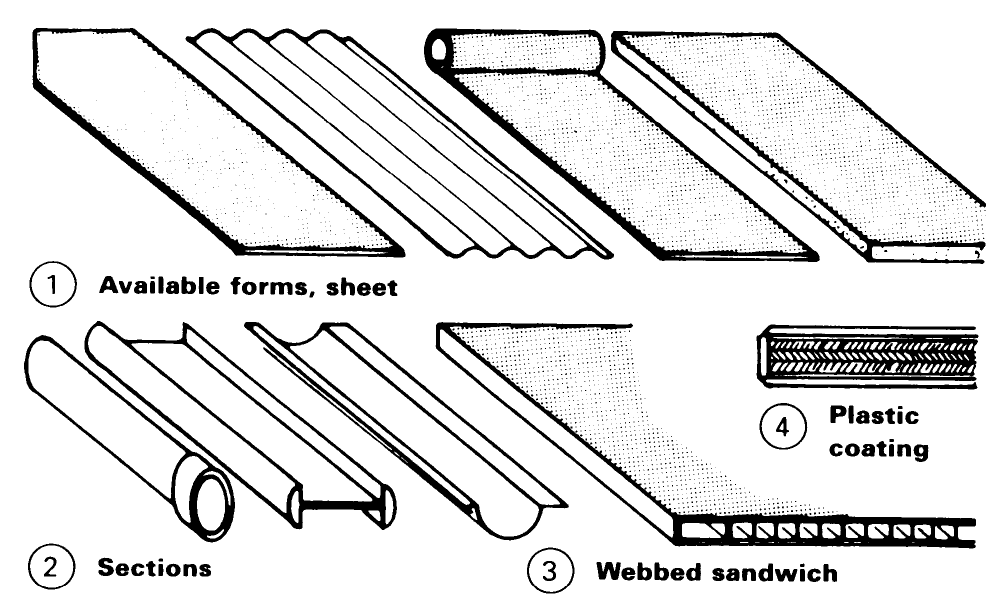

Plastics, as raw material (fluid, powdery or granular), are divided into three categories: (1) thermosetting plastics (which harden when heated); (2) thermoplastics (which become plastic when heated); (3) elastomers (which are permanently elastic). Plastics are processed industrially using chemical additives, fillers, glass fibres and colorants to produce semifinished goods, building materials, finished products – (1) – (6).

The beneficial characteristics of plastics in construction include: water and corrosion resistance, low maintenance, low weight, colouring runs throughout the material, high resistance to light (depending on the type), applications providing a durable colour finish on other materials (e.g. as a film for covering steel and plywood - (4) etc.). They are also easy to work and process, can be formed almost without limits, and have low thermal conductivities.

Double-skinned webbed sections are available in a wide range of thicknesses, widths and lengths. Being translucent, these sections are suitable for roof or vertical glazing. These are permeable to light - (3).

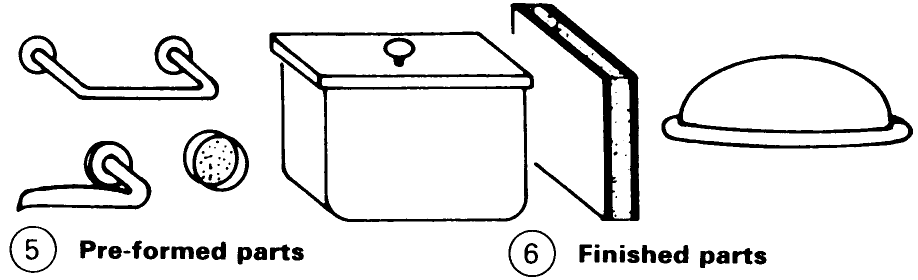

The large number of trade names can be bewildering so designers must refer to the international chemical descriptions and symbols when selecting plastics, to ensure that their properties match those laid down in standards, test procedures and directives. The key plastics in construction, and their accepted abbreviations, are:

The plastics used to produce semi-finished materials and finished components contain, as a rule, up to 50% filling material, reinforcement and other additives. They are also significantly affected by temperature so an in-service temperature limit of between 80° and 120° should be observed. This in not a serious problem given that sustained heating to above 80° is found only in isolated spots in buildings (e.g., perhaps around hot water pipes and fires). Plastics, being organic materials, are flammable.

Some are classed as a flame inhibiting structural material; most of them are normally flammable; however, a few are classed as readily flammable. The appropriate guidelines contained in the regional building regulations for the application of flammable structural materials in building structures must be followed.

Classification of plastic products for building construction.

(1). Materials, semi-finished: 1.1 building boards and sheets; 1.2 rigid foam materials, core layers; 1.3 foam materials with mineral additions (rigid foam/light concrete); 1.4 films, rolls and flat sheets, fabrics, fleece materials; 1.5 floor coverings, artificial coverings for sports areas; 1.6 profiles (excluding windows); 1.7 pipes, tubes and accessories; 1.8 sealing materials, adhesives, bonding agents for mortar, etc.

(2). Structural components, applications: 2.1 external walls; 2.2 internal walls; 2.3 ceilings; 2.4 roofs and accessories; 2.5 windows, window shutters and accessories; 2.6 doors, gates and accessories; 2.7 supports.

(3). Auxiliary items, small parts, etc.: 3.1 casings and accessories; 3.2 sealing tapes, flexible foam rolls and sheets; 3.3 fixing devices; 3.4 fittings; 3.5 ventilation accessories (excluding pipes); 3.6 other small parts.

(4). Domestic engineering: 4.1 sanitary units; 4.2 sanitary objects; 4.3 valves and sanitary accessories; 4.4 electrical installation and accessories; 4.5 heating.

(5). Furniture and fittings: 5.1 furniture and accessories; 5.2 lighting systems and fittings.

(6). Structural applications; 6.1 roofs and supporting structures, illuminated ceilings; 6.2 pneumatic and tent structures; 6.3 heating oil tanks, vessels, silos; 6.4 swimming pools; 6.5 towers, chimneys, stairs; 6.6 room cells; 6.7 plastic houses.

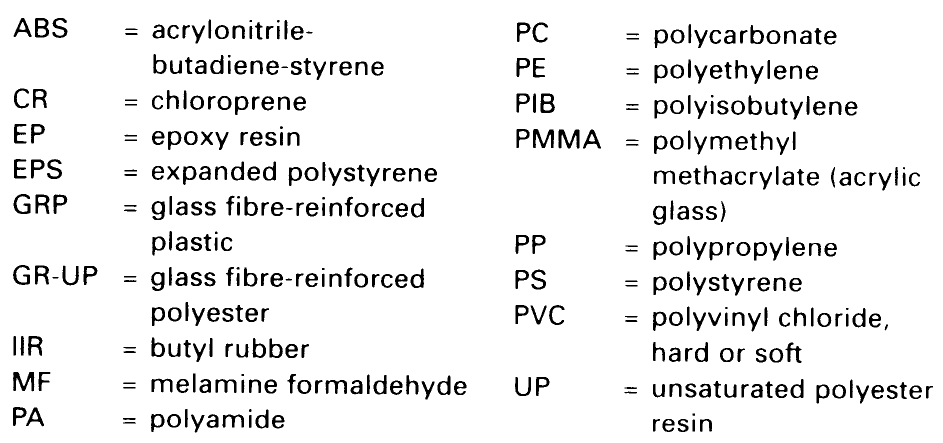

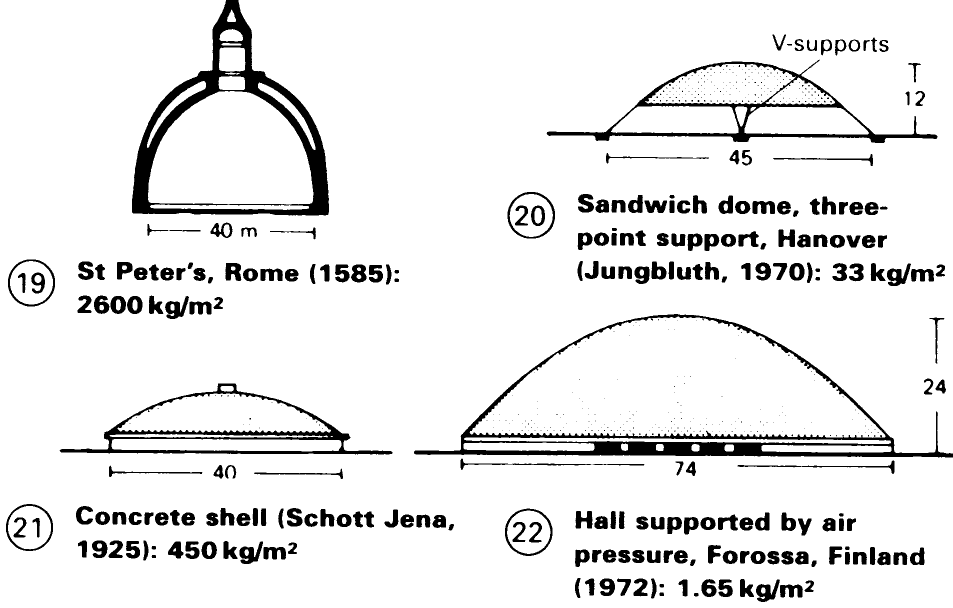

Construction using plastics is best planned in the form of panel structures (shells). These have the advantage of very low weight, thus reducing loading on the substructure, and also offer the possibility of prefabricated construction (14) – (17). Structures in plastics (without the use of other materials) at present only bear their own weight plus snow and wind loads, and possibly additional loads due to lighting. This allows large areas to be covered more easily – (19) – (22).

Date added: 2023-01-01; views: 965;