Main Bearing Cap Bolt

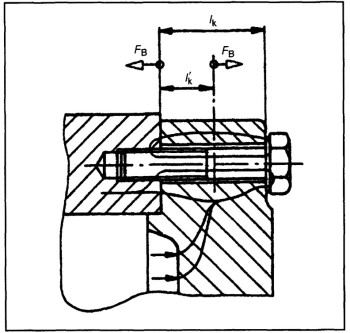

The main bearing cap bolts connect the main bearing caps with the engine block at the crankshaft bearings. As a rule, two such bolts are used for each main bearing cap; these are usually fully threaded, collared bolts and may be used with washers. Figure 7-326 shows the installation situation for such a connection and the associated force flows. Here

Fig. 7-326. Installation situation and force flow at the main bearing cap bolt

The critical problem when designing this configuration is the tight installation space available for the bolt head in most instances. Very close attention must be paid to maintaining the permissible surface pressure for the rear of the bolt head and its mating surface.

Every main bearing cap bolt is installed twice: the first time for machining the bearing shell seat to press-fit dimensions and then again after assembling the crankshaft and positioning the bearing caps. In the second assembly cycle, seizure may occur at the threads if the bolt exhibits damage such as impact dents at the tip or start of the threading.

This is avoided preventively in screw engineering with ideal tip design and in manufacturing with the shortest possible drop heights (maximum 300 mm). The design of the tip is understood to include chamfering the start of the screw shaft before rolling the threads to ensure that the threads do not break out during rolling. At the start of the thread there appear only dull thread teeth that are not inclined to dent in response to impact.

To increase the engine block stiffness, the so-called ladder frames are used more frequently in engines to interconnect individual main bearing caps. In this way, the lower section of the engine can be stiffened to avoid twisting and warping. Usually the bearing caps are cast in place in the ladder frame made of aluminum. In this case the main bearing bolts are used to fix the complete unit in place.

Tightening processes using the 0.2% offset limit or the rotation angle as the lead variable have become the most common assembly techniques.

Date added: 2024-07-30; views: 550;